Battery Motor for drum and IBC pumps

Mobile performance. Smart and maintenance-free.

Smart

From display to interface for peripherals – smart technology and all relevant

features of the FBM 4100 explained in a compact format.

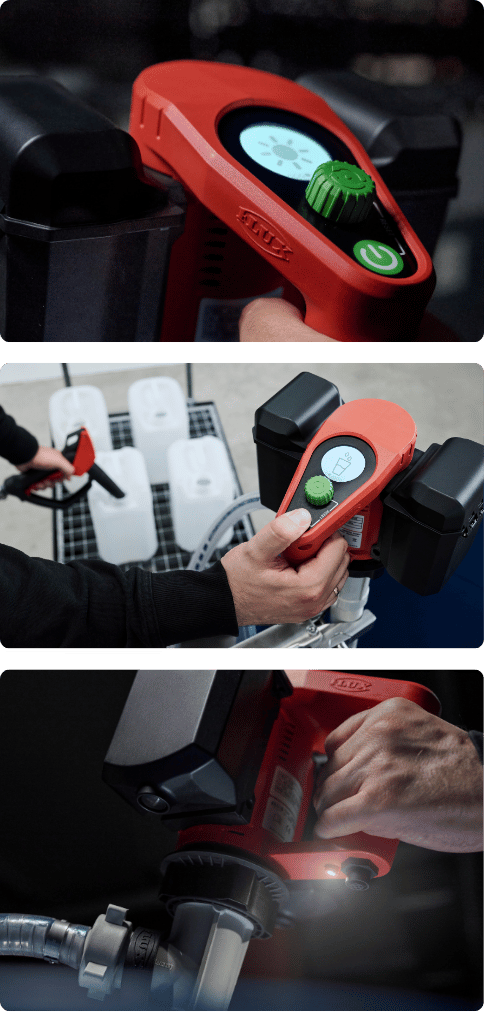

Intelligent control with LCD

All information at a glance: The Battery Motor shows the speed, battery status, and filling profiles directly on the clear display – for maximum control and precision when pumping.

Batch fill. Repeatable fill at the touch of a button.

The FBM 4100 makes it easy to program filling quantities. Up to 6 filling profiles can be saved and stored for recurring tasks. These profiles can then be repeated as often as desired at the touch of a button, without the need for a flowmeter.

Integrate peripherals. Control filling processes precisely.

FBM 4100 Pro expands the core model with a 5-pin interface with power supply. This allows external devices such as float switches, start/stop buttons, and flowmeters to be connected directly.

Digital evaluation via FLUXTRONIC® is also supported – for maximum precision in repeatable filling processes.

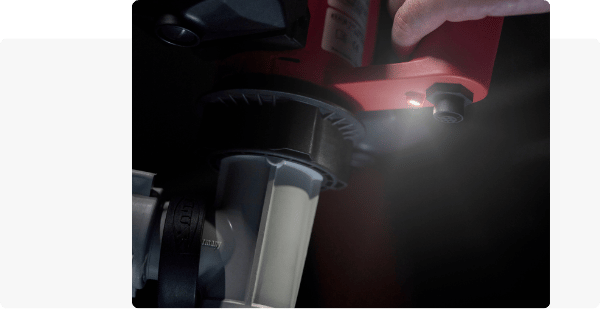

LED lighting

See better, fill more precisely: The integrated LED light ensures a clear view of the medium – even in poor lighting conditions. Ideal for dark rooms or container.

Dry-run protection

When dry-running protection is activated, the FBM 4100 automatically detects when no more medium is being pumped and stops the motor immediately. This reliably protects the pump and sealing system from running dry and significantly extends their service life.

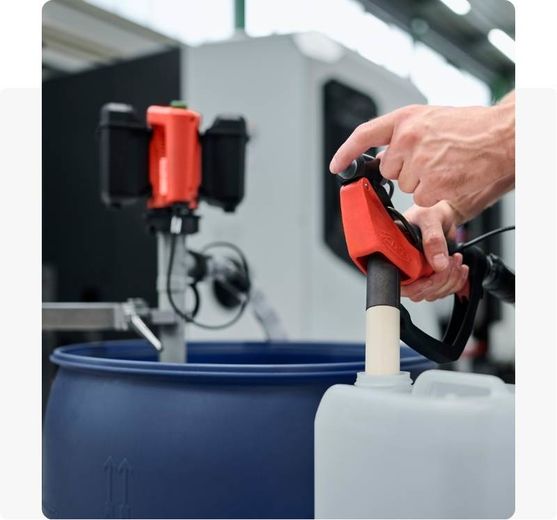

One battery motor for all.

Also for third-party pumps.

The FBM 4100 is compatible with all FLUX pumps in the 400 series and the VISCOPOWER F 570. It also makes pumps from other manufacturers powerful and mobile – thanks to battery technology and smart functions. Ideal for anyone looking for performance, mobility, and future-proofing.

Independent. Made for long days.

28 drums or 5 IBCs without changing the battery (at approx. 10,000 rpm).

Determined with water (20 °C) at free outlet (directly at the pressure connector), maximum flow rate measurement. Tolerance: ± 10%. Example A ( approx. 10,000 rpm): 5,500 l in 32 min → approx. 28 × 200 l drums or 5.6 IBCs. Example B ( approx. 6,000 rpm): 11,000 l in 100 min → 55 × 200 l drums. Measurement configuration: F 430 PP 50/38 (pump tube). Note: The values refer to the above setup and are for comparison purposes only. Other media, temperatures, or configurations (e.g., hose length/diameter, fittings) will produce different results.

See performance with pump kit in real world conditions

Technical data

Performance data and specifications of the FBM 4100 at a glance.

| Feature | Description |

|---|---|

| Power | 420 W (ventilated housing) 260 W (closed housing) |

| Type | Brushless motor, maintenance-free |

| Speed range | 5,500 to 12,250 rpm, adjustable in 10 steps |

| Runtime / delivery quantity, max. | 28 drums, 5 IBC |

| Delivery rate, max. | 218 l/min, 30 m WS |

| Viscosity, max. | 5000 mPas |

| Compatibility | FLUX 400 series, VISCOPOWER F 570, MINIFLUX, third-party pumps |

| Battery | 2× 18V / 4 Ah Li-Ion, Einhell Power X-Change (Other Einhell 18V batteries can be used; use without protective cover / with reduced IP protection if necessary). |

| Charging | Approx. 75 min (Einhell Power X-Twincharger) |

| Protection class | IP24 (ventilated housing) IP44 (closed housing) |

| Display | LCD |

| LED lighting | 200 lumens |

| Explosion protection | No explosion protection |

| Weight | 2.8 kg (including batteries and protective covers) |

Functions

All smart functions of the FBM 4100 – including the advanced PRO features.

| Function | Description | Core | Pro |

|---|---|---|---|

| Batch filling | Exact repetition of filling quantities*, 6 filling profiles | ||

| Dry-run protection | Stops automatically when container is empty | ||

| Usage data | For predictive planning and maintenance | ||

| Interface for peripherals | e.g., flowmeter, level sensors, float switches | ||

| FLUXTRONIC® connection | Digital evaluation and control of delivery quantities | ||

| External start/stop buttons | e.g., directly on the hand nozzle |

*Deviation less than 2% for 3-liter fill, depending on medium, viscosity, and pump.

FBM 4100 Pro

All functions of the FBM 4100 Core, supplemented by a peripheral interface with power supply.

The FBM 4100 Pro includes a powerful 5-pin interface. This allows peripheral devices to be connected directly and supplied with power ( 24 V to 100 mA) – without the need for additional control boxes or external electronics.

This makes semi-automatic filling tasks much easier to implement.

- Start/stop button: Direct control of the delivery process, for example at the hand nozzle.

- FLUXTRONIC® evaluation unit: Digital dosing control and precise monitoring of filling quantities.

- Flowmeter: Integration of external flow measurement systems for controlled filling processes.

- Other peripheral devices: Float switches or level sensors can be connected directly.

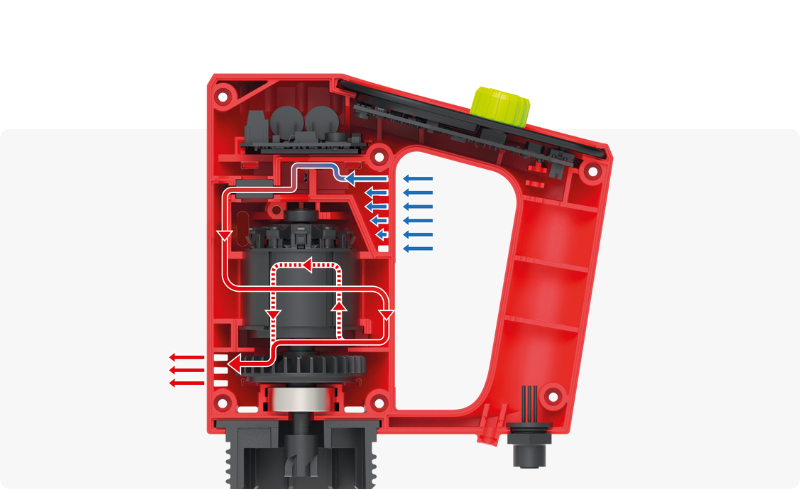

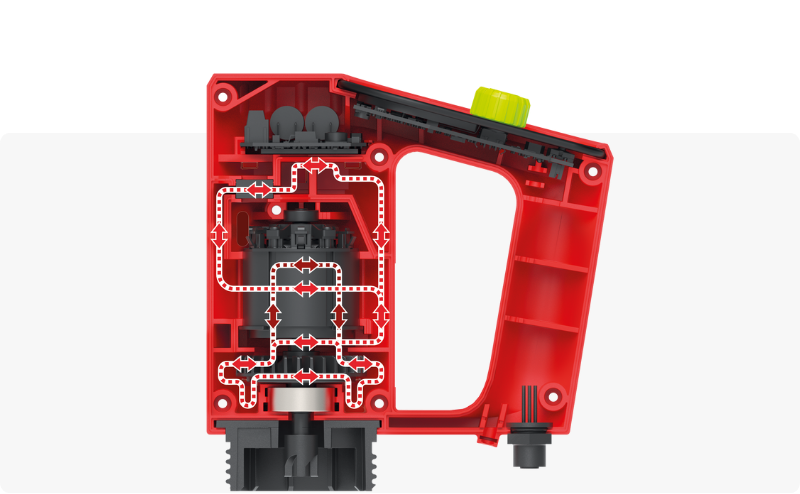

Two ventilation concepts

Maximum performance or maximum protection: choose the right variant for your application.

Maximum performance: ventilated housing

Ideal for standard applications where high performance is crucial. The motor is effectively cooled, ensuring consistently high performance.

- Maximum motor power of 420 watts

- Air-cooled motor, electronic components protected

- Protection class IP24 for general applications

Maximum protection: closed housing

Optimal for sensitive or aggressive environments. Fully encapsulated housing prevents the ingress of harmful vapors.

- Maximum motor power of 260 watts

- Fully encapsulated, protection against aggressive media and vapors

- Increased protection class IP44 for demanding conditions

Pump sets. Ready for immediate use.

Preconfigured sets consisting of motor, pump, and accessories—optimally matched to each other.

Pump sets combine motor, pump, hose, and hand nozzle. They are available in various designs and materials, optionally also with a pump stand.

Delivery rate using the example of pump set F430:

In combination with an F430 drum pump, 2 m hose, and hand nozzle, the FBM 4100 achieves a delivery quantity of up to 45 l/min. The pump set empties a 200-liter drum in approx. 4.5 minutes and a 1,000-liter IBC in around 22 minutes (measured with water).

Videos

From commissioning to smart functions – everything you need to know about the FBM 4100.

Functions and operation

Learn about assembly, operation and smart functions in short clips.

FBM 4100 uses Einhell Power X-Change

Reliable power supply with flexible battery options: The FBM 4100 uses two 18 V, 4 Ah batteries from the Einhell Power X-Change series and the Power X-Twincharger 3A charger. For long runtime and fast charging.

Power X-Change Plus batteries:

- High performance, shock protection, and good grip

- Low self-discharge, no memory effect

- Batteries with other capacities are supported

Power X-Twincharger 3A:

- Full charge of both included 4.0 Ah batteries in approx. 75 minutes

- Fast charging function and battery monitoring

- Parallel charging of two batteries

Support & downloads

All documents relating to the FBM 4100 battery motor – in your language and always in the latest version.

Documentation

User Manual

for FBM 4100

Technical Data Sheet

Characteristics, interfaces, and compatibility

Brochure

Overview, benefits, and operating range

FAQ

Quick help with selecting, using, and configuring your FBM 4100

Which pumps are compatible with the FBM 4100?

The FBM 4100 battery motor is compatible with all FLUX pumps in the 400 series, MINIFLUX series, VISCOPOWER 570, and many other brands—thanks to adapters.

Is an adapter for third-party pumps included?

For reasons of sustainability and to avoid unnecessary parts, the adapter is not included in the standard scope of delivery. It can be ordered at the time of purchase. Do you have questions about compatibility? We are happy to advise you

How long does a battery charge last in practice?

With one battery charge, up to 28 drums (200 l) of water can be filled at high delivery rates. With reduced delivery rates and adjusted speeds, it is often possible to fill more drums per battery charge. The actual runtime depends on the medium being pumped, the delivery head, and the power level setting, and in many applications is sufficient for a full working day without changing the battery.

What is the difference between the Core and Pro versions?

The Pro version offers an additional interface with integrated power supply for external devices such as flowmeters, float switches, level sensors, start/stop buttons, and integration with FLUXTRONIC®. The basic technical data remains identical in both versions. Compare technical data and functions

Can I also use the Battery Motor in the food industry?

Yes, in combination with FLUX stainless steel pumps such as the F 430 S, the FBM 4100 is also suitable for hygiene-critical applications. We would be happy to advise you personally.

What happens when the container is empty?

When the integrated dry-run protection is activated, the FBM 4100 automatically detects an empty container and switches off the motor before damage occurs. This protects your pump, saves energy, and secures the process.

How do I activate the dry-run protection of the FBM 4100 battery motor?

First, place the pump in a container filled with medium. Activate the dry-run protection via the device menu: press the rotary knob, select dry-run protection, and confirm again. Then set the desired speed and start the motor—the dry-run protection symbol appears briefly on the display as soon as the dry-run protection is active.

What smart functions are integrated into the motor?

The FBM 4100 battery motor offers batch filling with 6 filling profiles, LCD display, dry-run protection, LED lighting, and runtime display – all available directly on the device. View all smart functions

How long does it take to charge the battery?

The charging time is approx. 75 minutes for both batteries (2× 18 V / 4 Ah, operated in parallel) with the Einhell Power X-Twincharger.

Can I use other/larger batteries?

The FBM 4100 battery motor is compatible with all 18 V batteries from the Einhell Power-X-Change series. The protective covers can accommodate batteries with a capacity of up to 4 Ah, which means that the overall device achieves protection class IP24. If the protective covers are removed and protection class IP24 is not required, batteries with a larger capacity can be used. Currently, up to 8 Ah is possible, which means that even longer motor running times can be achieved.

Should I remove the batteries for storage?

Yes. For longer periods of storage, the batteries should be removed from the motor and stored separately in the proper manner.

How should I store the motor?

Always store the motor in a dry, clean, and dust-free place. Before prolonged storage, the motor should be cleaned and stored without the pump or Accessories.

Measured values and their significance.

Why laboratory values are important. (Comparability)

In order to objectively demonstrate the performance of the FBM 4100, we determine all performance data under defined, industry-standard laboratory conditions on the test bench. These measurement methods enable a comparable, reproducible, and fair evaluation, both within our portfolio and in comparison to the market.

Why results vary in practice.

In real-world applications, many factors influence the actual delivery rate achieved, including: medium and viscosity, temperature, hose length and diameter, filling unit (e.g., hand nozzle), pump unit, and delivery head. Therefore, the values determined on the test bench may vary in practice, either upward or downward.

Our claim: realistic values for your application.

As a manufacturer, we not only want to provide comparable laboratory values, but also enable you to make a realistic assessment for your specific application. That is why we are happy to assist you in selecting the right pump set and provide you with practical guidelines that are as close as possible to your real-world application.

On request, we will be happy to advise you, tailored to the medium, design, and operating conditions.

Our performance curves, which illustrate the relationship between delivery rate, delivery head, and design, also offer practical guidance.

Delivery volume for pump set based on speed, real world conditions

High speed for maximum delivery rate, reduced speed for maximum delivery volume per battery charge. This allows the performance of the battery motor to be adapted to the application.

FBM 4100 in a set with F 430 PP 40/33, 2 m hose and hand nozzle.

| Speed | 6.250 rpm | 8.500 rpm | 10.000 rpm | 12.250 rpm |

|---|---|---|---|---|

| 200-litre drums | 14 | 11 | 9 | 6 |

| IBCs | 3 | 2.2 | 1.8 | 1.2 |

| Delivery rate | 33 l/min | 45 l/min | 56 l/min | 64 l/min |

| Battery life | 90 min | 49 min | 32 min | 19 min |

| Total delivery quantity | 2970 l | 2205 l | 1792 l | 1184 l |

Determined with water (20 °C)

Pure power made in Germany!

FLUX has been producing pumps, motors, and accessories exclusively in Germany for over 70 years. With its own production facility, welding shop, motor winding shop, plastic injection molding shop, and assembly facility in Maulbronn, Swabia, FLUX can rightly claim to produce 100% MADE IN GERMANY. Low staff turnover, a family-like atmosphere, employees with decades of experience, and continuous training of young talent are the recipe for success behind FLUX's unparalleled product quality.